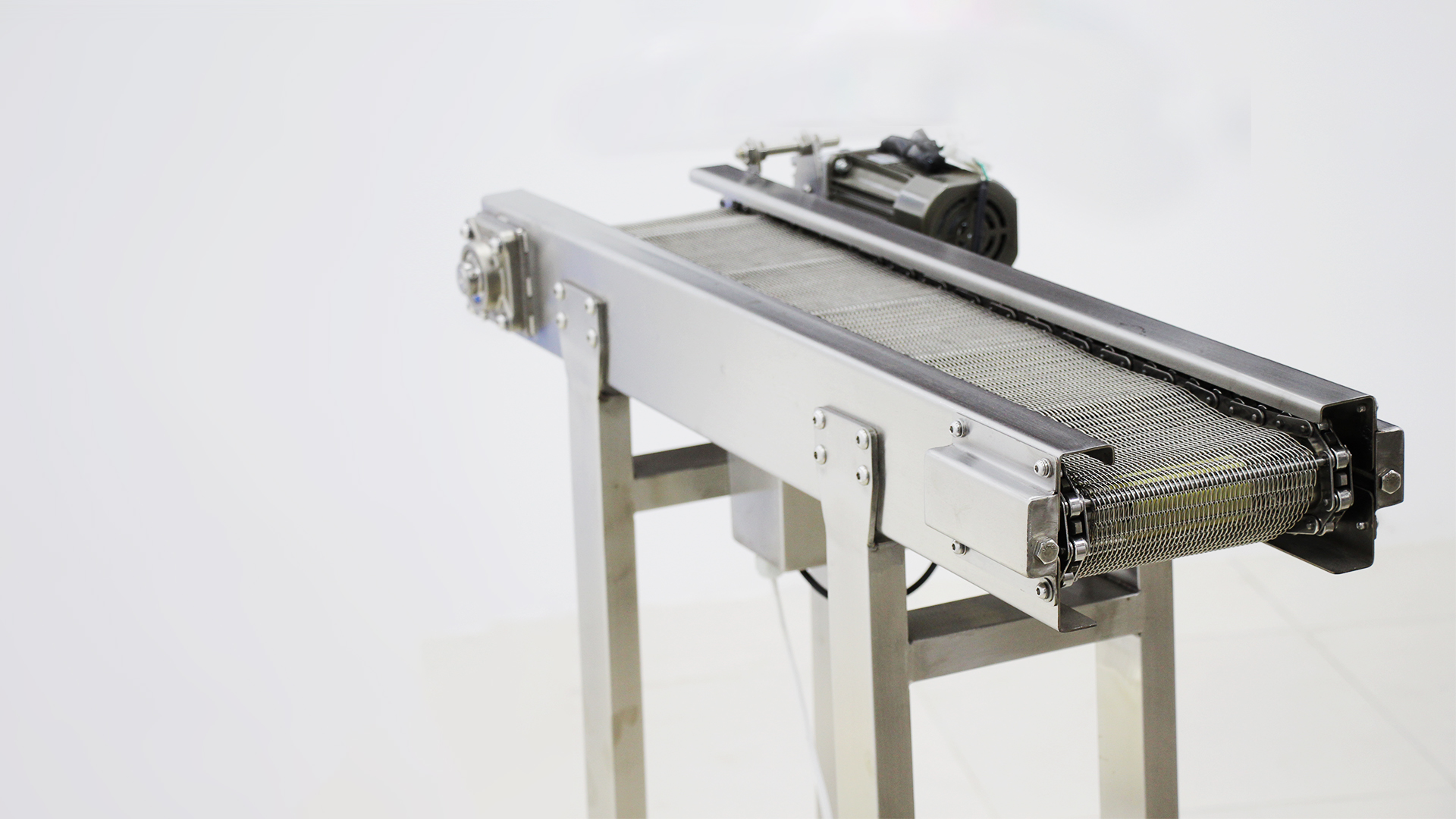

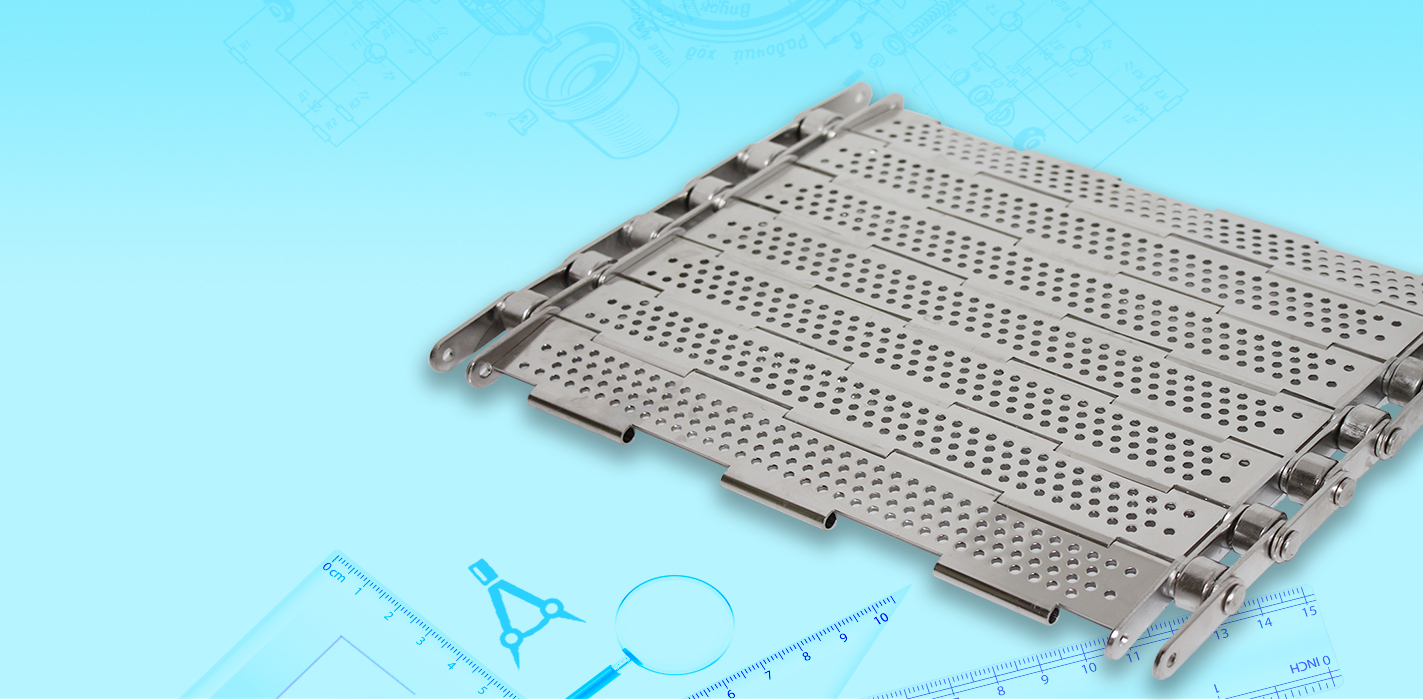

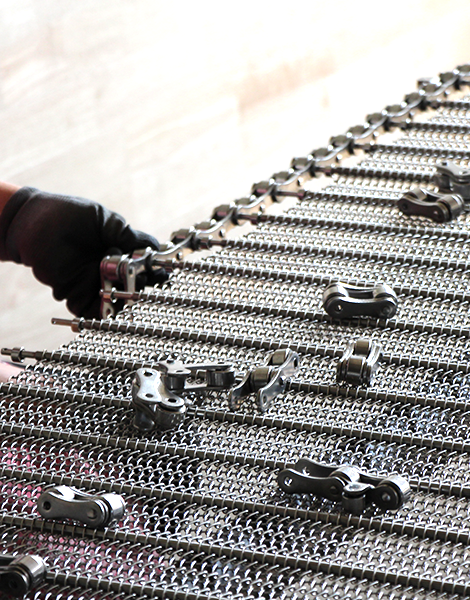

Due to their flexibility, efficiency, and hygienic properties, flexible chain conveyors are widely used across multiple industries. They are used in pharmaceutical manufacturing, food and beverage processing, cosmetics production, tobacco processing, paper product manufacturing, dairy processing, bearing and mechanical part processing, electronic component assembly, and packaging line operations. Specific application scenarios are as follows:

Pharmaceutical Manufacturing Industry:

Flexible chain conveyors comply with GMP standards. The equipment operates without lubrication, is corrosion-resistant, and runs at noise levels below 30 decibels. It operates automatically and smoothly to meet cleanliness requirements for pharmaceutical packaging and transportation.

Food and Beverage Industry:

Flexible chain conveyors are water- and oil-resistant, easy to clean, and can be washed directly or submerged, meeting the food industry's hygiene requirements. They are ideal for the hygienic transport of bottled and canned products, as well as sanitary-grade transfer in baking product cooling sections.

Cosmetics Industry:

Flexible chain conveyors are sleek and aesthetically pleasing. They are easy to install and have standardized structures. They operate cleanly without contamination. They are ideal for cosmetic production processes, such as packaging lines for face masks and serums. Tobacco Industry: The high hygiene standards and flexible layout capabilities of flexible chain conveyors enable them to meet the tobacco industry's stringent demands for a productive environment and efficient logistics.

Paper Products and Dairy Industry:

They reliably transport paper products, such as rolls, while preventing contamination and meeting hygiene and efficiency demands in dairy production. Bearing and Mechanical Parts Processing: They automate component handling for cleaning, machining, and other processes, thereby boosting production efficiency.